We provide turnkey solutions for cleaning, flavoring and mixing different varieties of teas (Dust Grade, Fannings, BOP, OPA etc.) to ensure consistent, quality end product.

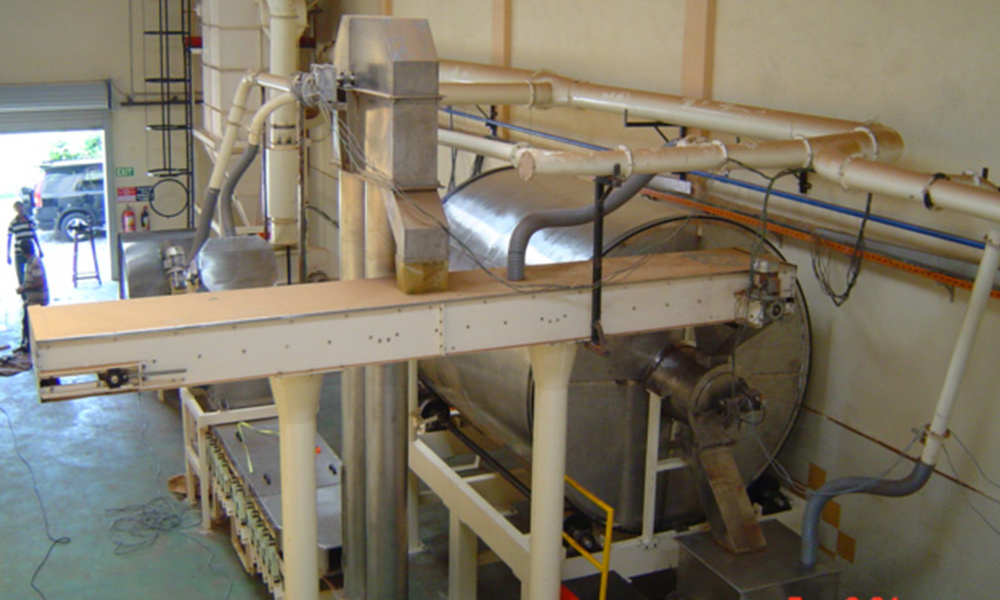

The cleaning line guarantees removal of contaminants. Light particles such as paper, plastic, agro contaminants that naturally come with the teas etc. are removed using a series of accessory conveyors. Ferrous and non-ferrous particles are removed using our specialty magnetic equipment. The heavier foreign particulate matter is removed with our state-of-the-art pneumatic de-stoner. The clean tea is fed to our rotary blending drums of various capacities for blending batches of tea. In case flavoring of tea is required, a flavoring contraption can be added onto the blending drums to add liquid/ solid flavor in desired percentages.

We provide cleaning lines up to 6,000 Kg/ hour and rotary blending drums of capacities up to 2,000 Kg/ batch.

Technical Specification

— Pneumatically operated tipper with feed hopper

— Vibro sieve with plate magnet (for high reach – to separate heavy ferrous contaminants viz. nails, washers, etc.)

— Accessory conveyors – belt/ screw/ gooseneck/ vibro (with suitable mesh) – to convey tea/ remove larger contaminants

— Fluff extraction system – to remove very fine contaminants such as fluff, hairs etc.

— Drum Magnet – to remove fine ferrous particles such as iron filings etc.

— De-stoner with air-product separator – to remove stones and heavier materials

— Non-ferrous metal detectors

— Bucket elevators

— Storage silos

— Blending drums of varying capacities – 100 Kg, 250 Kg, 500 Kg, 1000 Kg, 1500 Kg

— Mobile silos

— Completely electronic automation including SCADA, if required