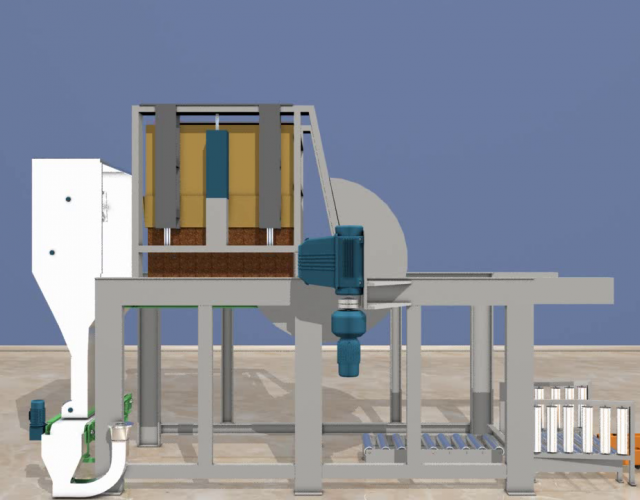

Fully automated, customizable and extensible pneumatic tobacco feed systems that regulate and deliver tobacco to the cigarette makers from the raw material storage area. The system comprises of:

- Opti-pulsejet Bag filters – automated, self-cleaning with a choice of filters including polyester/ pleated filter fabric bags. They can be customized from 1 to 15 cigarette makers

- Centrifugal Fan – customized, self-cleaning heavy duty fans

- Rotary Airlock – periodically dispel dust from bagfilter

- Accessory Conveyors – belt/ screw/ vibro conveyors

SS/ PVC piping - Bale Tippers – customized to serve single/ multiple cigarette makers.

- Holding conveyors/ Vibro sifters – hold buffer quantities and loosen tobacco

- Discharger Boxes – to make older cigarette makers pneumatic ready

The above system comes complete with logic/control panel to ensure synchrony across machines to reduce starvation at the cigarette makers.

Technical Specification

— Polyester/ cylindrical bags/ pleated bags or envelope bags

— Centrifugal blower of self-cleaning type blades

— Screw conveyor with rotary airlock valve

— Sequential timer & automation to control the process